Back River WWTP Headworks and Equalization CMAR

Dating back to 1911, the Back River WWTP is Baltimore’s oldest and largest treatment plant, with a peak design flow of 400 MGD. This large upgrade to the plant included a new headworks, influent pump station, and flow equalization tanks which serve to balance plant influent flow during wet weather.

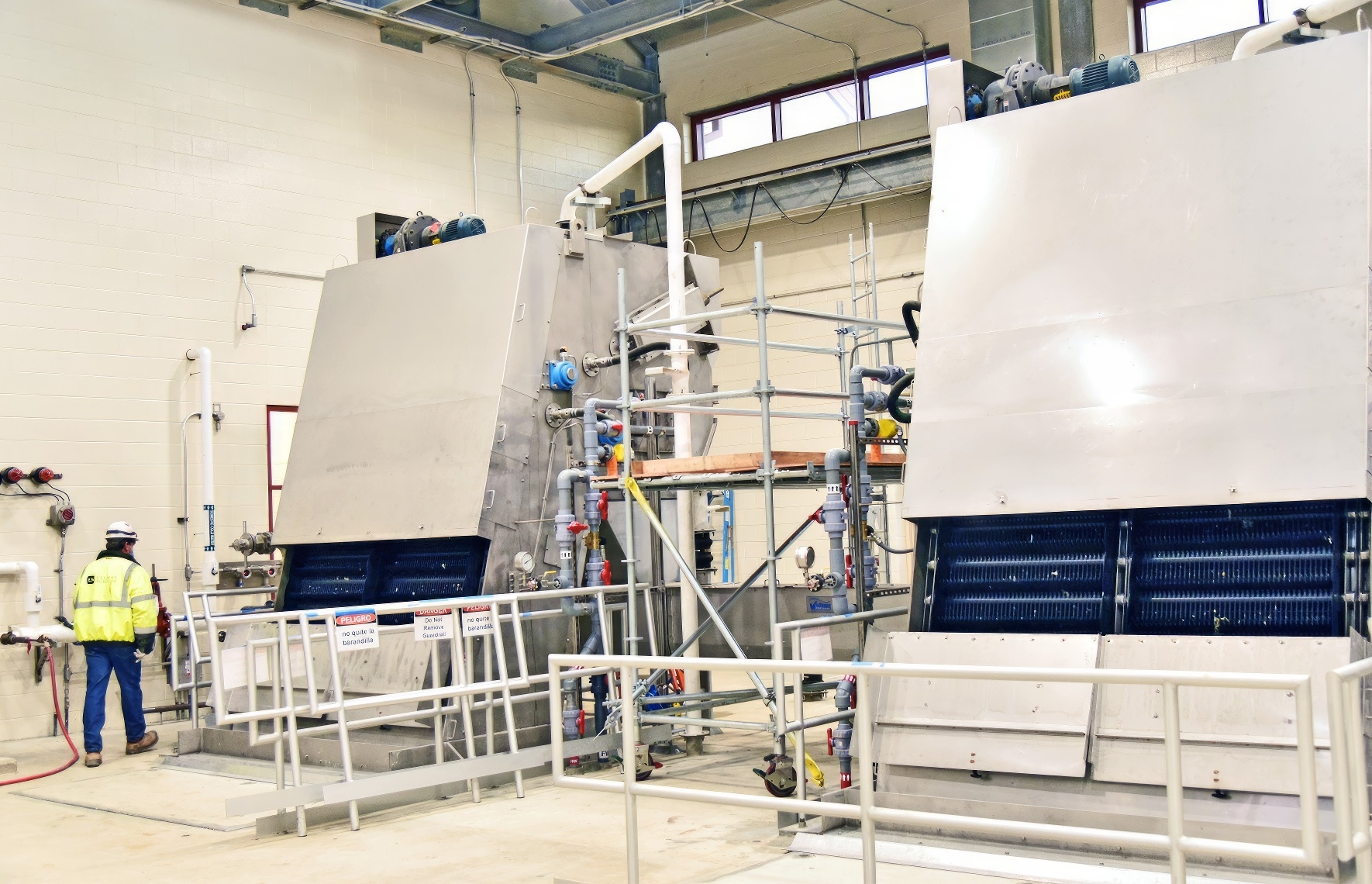

As may be anticipated when providing in-stream systems for a 400 MGD plant, everything about the project was “super-sized”. The sixty-foot-deep pump station houses eight 48” pumps with medium voltage motors up to 1500 HP. The headworks complex includes six 96” screens and an eight-bay traveling bridge-style grit removal system. The project also included a coarse screen facility, fine screen facility, two equalization tanks, generator, and odor control facility. Preconstruction services provided by our team included budget and schedule development, value engineering, alternative scope analyses, preferred equipment negotiation and procurement, and best-value subcontractor solicitation, bidding, and evaluation.

Our CMAR team made full use of BIM technology throughout the project. During preconstruction, 3D models were used to help visualize the various structures. As the design was finalized, detailed 4D schedules helped determine crane logistics and site access at various stages of construction. During construction, the BIM model was utilized to develop installation drawings and to generate supporting information for RFIs and record documents.

- Location: Baltimore, MD

- Owner: City of Baltimore, MD

- Engineer: JMT

- Contract Value: $429 Million

- Contract Awarded: 2017

- Contract Type: CMAR